German luxury-auto maker BMW Group has unveiled significant advancements in electric-drive technology with the introduction of the sixth generation of the BMW eDrive technology, pivotal for fully electric Neue Klasse vehicles. The new developments include an in-house developed and produced intelligent central control unit named the Energy Master, a high-voltage battery concept promising enhanced energy density, faster charging and longer range, along with a flexible approach to electric-motor production utilizing different motor types, ensuring flexibility and technology-openness.

The BMW Group emphasized its commitment to electric mobility and a technology-open approach to cater to diverse mobility needs worldwide. The Neue Klasse model, benefiting from the Gen6 eDrive technology, will debut in series production later this 2025 in Hungary.

This technology introduces an 800V high-voltage battery concept, resulting in a 30% faster charging speed and 30% increase in range for certain models. The design allows for integration into various models, making the battery a structural component of the vehicle and introducing bidirectional charging as a standard feature. These advancements are supported by the development and production expertise concentrated in Bavaria and Austria, covering the entire electric-mobility value chain.

Further insights detail the "local for local" approach for high-voltage battery assembly and the establishment of five new production facilities near BMW vehicle plants, enhancing production security and job creation. This principle extends to the supplier network for battery cells, with contracts for five battery cell factories across Europe, mainland China and the US. Innovations in battery production follow the "cell-to-pack" and "pack-to-open-body" principles, with numerous patented innovations by the BMW Group.

Recycling processes for high-voltage batteries at the end of their life cycle are being developed in partnership with SK Tes and other partnerships in the US, Mexico and Canada, focusing on a closed-loop approach for the sustainable integration of recovered materials into new battery production. Additionally, the BMW Group is pioneering direct recycling methods for residual materials from battery cell production.

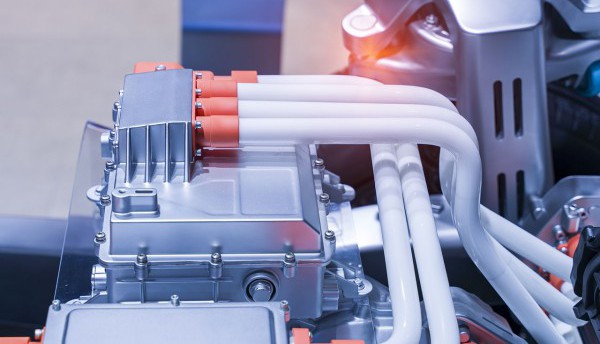

The new Gen6 eDrive system maintains the principle of an electrically excited synchronous motor (EESM), with improvements in efficiency, power output and a major upgrade for compatibility with the new 800-V architecture. The inclusion of asynchronous motor (ASM) technology alongside EESM technology illustrates the BMW Group's technology-open approach, allowing for a wide range of electric-motor configurations to suit customer preferences.

Finally, the production of Gen6 electric drive systems is set to begin at BMW Group Plant Steyr in summer 2025, leveraging the plant's longstanding expertise in drive systems. This move is expected to safeguard jobs and expand the plant's role in electric mobility. Thermal management developments at Steyr are crucial for optimizing performance parameters such as range and charging time. Plant Landshut has emerged as a major component provider, innovating in manufacturing processes and technologies, including a €200 million investment in the light metal foundry to support the Neue Klasse project.

This content may be AI-assisted and is composed, reviewed, edited and approved by S&P Global.