Continental has developed a new generation of brake boosters which will be around 50% lighter in weight compared with its predecessor, according to the company press release. The weight of the new brake booster has gone down drastically by 1,700 grams and is 12% (15 millimetres) shorter.

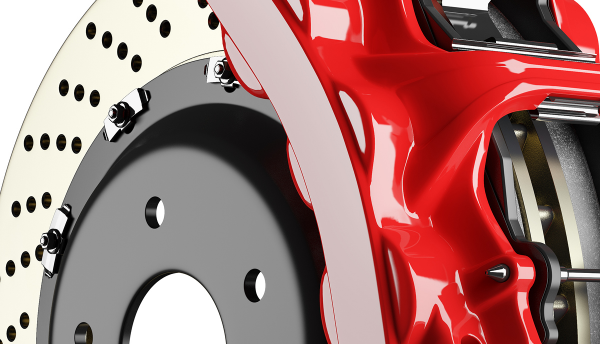

Significance: Continental achieved weight reduction in its product by using thinner metal and optimising components’ internal dimensions. The metal thickness has been reduced by 50% from 2.4 millimeters to 1.2 millimeters without compromising its service life compared with traditional aluminium technologies. "For this third generation, we have developed for the first time a full-aluminium brake booster. By reducing the wall thickness of the metal parts and producing an extremely small fitting length, the booster unit is even lighter and saves even more space than its predecessors", said Stephan Krebs, Vice President of R&D Actuation Systems in the Hydraulic Brake Systems Business Unit at Continental's Chassis & Safety division. The demand for brake boosters is expected to grow as they form an essential part of safety systems including anti-lock braking systems (ABC), electronic stability control (ECS) and advanced driver assistance systems. Coupled with weight reduction and compactness benefit offered in the latest generation brake boosters, the product is likely to gain an edge over its competitor’s product. The brake boosters provide the necessary hydraulic pressure in the brake calipers for an effective braking power.